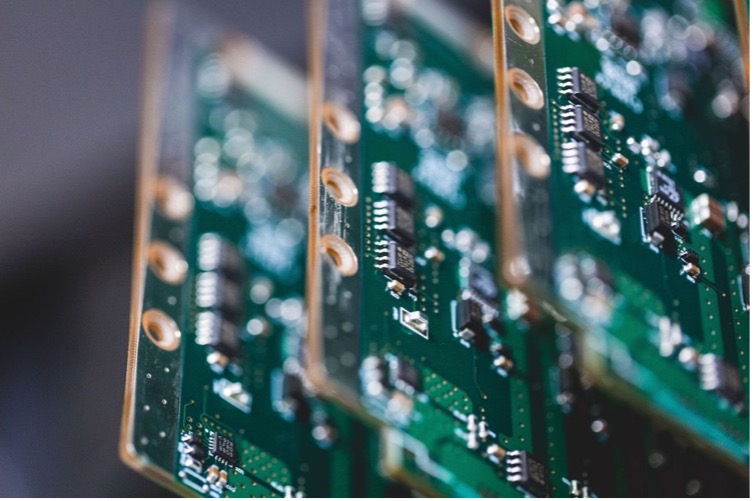

Any small shifts in consumer preferences or developing technology can have an enormous impact on the printed circuit board business, which in turn affects how PCBs are used and produced. Here are the five most important tech trends that will likely shape the PCB industry in the near future.

- Environmentally Friendly Production

PCBs are just another product on the market. They’re not quite like everyone else, yet political, climatic, and social factors can still have a significant impact. Because of the global rush towards sustainable production, it is imperative that PCB manufacturing methods keep pace.

When it comes to the intersection between legislation and industry practices, PCB producers have always been in the limelight. Examples include the introduction of lead-free solder, which necessitated energy-intensive production procedures. Since then, the industry has had to adjust to a new balance.

PCBs have also been competitive and innovative in other respects. Fiberglass has long been used as a substrate for PCBs because it is widely perceived as being ecologically safe. As technology keeps getting better, it may be replaced in the future by copper with a resin coating or liquid crystalline polymer.

As industrial operations of all kinds continue to balance their footprint with a warming planet, this green politics versus what’s expedient for manufacturing enterprises will certainly become the new standard.

- High-Density Interconnect

Smaller and smaller devices with better capabilities, especially routing traces, necessitated the development of high density interconnect (HDI). A PCB stack up with fewer layers and high-speed signal transmission is made possible by this ability. Due to the difficulties in making traces that can be routed via smaller spaces, noise and interference are a concern for HDI manufacture. ELIC and ALIC, which are extensions of this notion, are expected to increase in popularity in the coming years.

- COTS Components

One of the latest trends is the use of commercially available components, or COTS. The use of commercial-off-the-shelf (COTS) components in key space-based systems is thought to provide some standardization and reliability. Corporatization of the space manufacturing business may lead to a reduction in the regulatory oversight of components used in spacecraft.

- Auto-Placement of PCBs

Autoplacers are becoming standard equipment for PCB designers. The automation of this process has improved greatly, allowing electrical devices to run more smoothly. Automating the process of creating autorouters saves a significant amount of time. Consequently, these techniques have shortened the time it takes to get a product to market and increased operational quality.

As a result, manufacturers are striving to include CAD systems into their workflow. The manufacturing of PCBs, in particular multilayer boards, has been made considerably simpler and more efficient by the development of tools like autoplacers and adaptable software tools.

- Non-toxic PCBs

Managing electronic trash has become a global challenge. Biodegradable PCBs are becoming more popular as a solution to these issues. PCBs, which are often the bulkiest parts of electronic gadgets, are hazardous to the environment when disposed of because of the chemicals they contain and the fact that they cannot decay. There are no difficulties with biodegradable products. A few PCB manufacturers also believe that metals such as palladium and tantalum can be recovered from e-waste and reprocessed.

ChinaPCBOne Technology LTD. is the author of this article on PCB manufacturing. Find more information, about PCB manufacturers.